Architects, general contractors, and waterproofing contractors face a recurring question every Fall and Winter. Can we use our warm and hot weather silicone sealant for cold weather applications? Yes. Ease of installation, compatibility, and durability are key selection criteria.

It’s all about the chemistry. One-part silicone sealant use atmospheric moisture to assist the curing process. Cold weather decreases the availability of moisture in the air, thus extending sealant curing times. At the same time, cold weather increases the risk of adhesion failure, due to moisture or frost on the joint substrates. Clean, dry, and frost-free joints are one key to successful cold weather silicone sealant application. Ensuring sealant compatibility is another.

Cold Weather Sealant Application Glossary

- Cold Weather Temperature: 5 ℉ above the dew point temperature, typically 40 ℉ or lower

- Dew Point temperature: The temperature where air is unable to absorb any more moisture. Additional moisture falls as precipitation (rain, drizzle, fog) or condenses on cold surfaces (dew, frost), such as metal substrates.

- Gunnable: The ability to apply sealant using a caulking gun with normal effort

- Tooling: The act of shaping sealant already applied in an expansion joint using a caulk spatula to apply pressure and ensure adequate fill of the entire joint width.

- Cure Inhibition: The result when a chemical, substance or environmental condition inhibits a sealant’s ability to cure properly. Tooling aides such as solvents can contribute to cure inhibition.

- Silicone Rubber: Any of a class of synthetic materials which are polymers with a chemical structure based on chains of alternate silicon and oxygen atoms, with organic groups attached to the silicon atoms.

Cold Weather Silicone Sealant

Silicone sealant is durable, easy to apply and tool, able to adhere to most surfaces, available in multiple colors. All DOWSIL™ Silicone Building Construction Sealant remain pliable and easy to extrude (gunnable) in temperatures as low as -20 ℉. DOWSIL has 9 sealant rated for cold weather application:

- DOWSIL 790 Silicone Building Sealant

- DOWSIL 791 Silicone Weatherproofing Sealant

- DOWSIL 795 Silicone Building Sealant

- DOWSIL 995 Silicone Structural Sealant

- DOWSIL 756 SMS Building Sealant

- DOWSIL 758 Silicone Weather Barrier Sealant

- DOWSIL Contractors Weatherproofing Sealant

- DOWSIL Contractors Concrete Sealant

- DOWSIL 1199 Silicone Glazing Sealant.

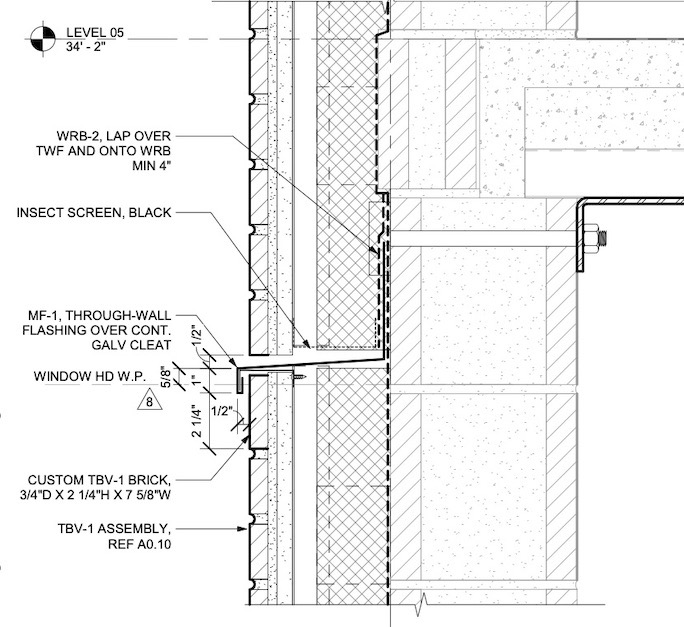

What is sealant compatibility?

Sealant compatibility classifies sealant as chemically suitable or unsuitable to come in contact with other types of construction materials. These products may include weather resistive barriers (WRB), self-adhered membranes (SAM‘s), liquid applied membranes (LAMs) and building cladding. Silicone sealant are fully compatible with other silicone products. Conversely, non-silicone sealant will not adhere to silicone products. We strongly recommended pre-construction adhesion testing of all substrate coming in contact with the specified sealant.

Cold Weather Silicone Sealant Selection

Whether you select silicone sealant depends on the type of project and the climate where you live. Product specifiers and contractors in Western Washington and Oregon seem to gravitate towards silicone sealant because of their ability to adhere to a wide variety of substrates. Silicone sealant , silicone coatings and silicone waterproofing are more common west of the Cascade Mountains, due to the wetter, milder climate.

The Yakima-Tri-Cities Metropolitan Area located in southeastern Washington is one place that prefers silicone sealant. DOWSIL Contractors Weatherproofing Sealant and Contractors Concrete Sealant are competitively priced while still rated for application down to -20 ℉. These two characteristics alone help to explain their popularity.

Sign of Trouble During Cold Weather Silicone Sealant Application

Unseen moisture or frost on the substrate is a typical sign of trouble during cold weather sealant application. Moisture or frost on both porous and non-porous substrates can affect long term adhesion of any type of sealant. It is imperative that you Follow Manufactures Instructions for proper joint preparation in cold weather applications.

Signs of Trouble After Cold Weather Silicone Sealant Application

Adhesion Failure, Movement During Cure, and Adhesive / Cohesive Failure are all signs of trouble after cold weather silicone sealant application.

Adhesion Failure

Adhesion failure can occur for a variety of reasons including improper joint preparation and tooling. Incorrect joint geometry and cure inhibition are also causes for concern.

Movement During Cure

Joint deformation can occur when sealant are applied to cold substrate. Rising temperatures and expanding substrate cause uncured sealant to lose adhesion, wrinkle, or bulge, instead of remaining concaved.

Adhesive / Cohesive Failure

Adhesive failure occurs when a sealant fails to adhere (stick) to the substrate. Causes include dirty, moist, or frosty joint surfaces. Cohesive failure occurs when the sealant splits or tears within itself.

Consult a Cold Weather Silicone Sealant Expert

Cold weather sealant application comes with its own set of challenges, including longer curing times, sealant/joint conditioning, and maximum joint widths. Consulting a cold weather sealant specialist or waterproofing consultant helps you to specify and apply the right sealant. Call your local Atlas Supply silicone sealant specialist today at 1-800-347-5767. Get the help you need to maximize your success and minimize the chance of sealant application/curing failures detailed above.

Citations

- Atlas Supply – DOWSIL High Performance Building (HPB) Silicone Solutions, Products & Technologies

- Atlas Supply – Sealants Glossary

- NOAA – National Weather Service – Dew Point vs Humidity

- Atlas Supply – Installation of DOWSIL Silicone Building Sealant in Cold Weather

- Oxford Dictionary – Definition of silicone.

Randy McAdams, Senior Outside Sales, Atlas Supply

Last Modified: July 15, 2021

What does Dow Corning Now Branded DOWSIL mean for customers? A new brand name, but the same trusted materials. Continuing warranty coverage. Stronger service and support. A new, easier-to-use website. And a new world of possibilities.

What does Dow Corning Now Branded DOWSIL mean for customers? A new brand name, but the same trusted materials. Continuing warranty coverage. Stronger service and support. A new, easier-to-use website. And a new world of possibilities.